With National Inventors’ Day coming up February 11, we celebrate our innovators’ ingenuity and ability to solve problems in ways that truly make a difference. Meet Xerox’s Michelle Chretien – she’s making the un-makeable.

Chretien is a materials scientist and research leader who specializes in electronic materials and 3D printing. She leads a multidisciplinary team of chemists, materials scientists and engineers at the Xerox Research Centre of Canada (XRCC). Her team at XRCC is creating revolutionary new materials the world has never seen before.

“What’s really exciting to me about 3D printing and printed electronics is not so much making conventional things in a different way, but the possibility to make things that were un-makeable before,” Chretien says. “I like to describe our work as being at the intersection of printed electronics and 3D printing. We want to produce unconventional objects by printing form and function together.”

Although 3D printing is a relatively new concept, Chretien believes the potential is massive—especially around avoiding material waste. Plus, the manufacturing portability could make it possible to take a small 3D printer up to a space station or down to a mine to produce things on the spot.

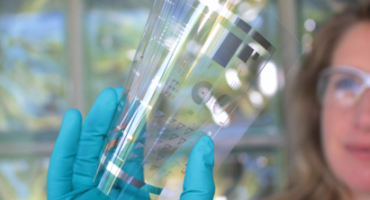

Her research team is developing new types of “smart” inks that can add functionality to everything from wearables to automotive. They’re also integrating materials with different printing technologies, such as coupling digital printing with robotic motion control to print on all sorts of objects, not just flat surfaces.

“We’re looking at being able to print really interesting circuits and sensors on, or in, three dimensional objects,” Chretien says. “The aim is to put all the pieces together so when an object is produced, you’re adding in electronic circuitry along with the structural elements to generate a complex, interesting and functional object.” Eventually, this will enable designers to create new products that aren’t limited by the shape of a conventional circuit board.

The possibilities are endless:

- Perfect-fitting glasses printed following a scan of the face, with sensors and displays embedded in the lenses

- A mouth guard with embedded sensors that monitor your blood oxygen, heart rate and glucose levels

- Pipes with sensors printed directly onto the surface to detect water flow, chemical spills, or oil and gas leaks

With Chretien and her team inventing materials that have new functions or combine different properties—such as conductive plus rubbery, or thermally insulating and really robust—there’s no telling what they’ll think of next, or which customer’s problem they’ll solve with a brand-new material.

“I really enjoy talking to our customers,” Chretien says. ”When someone comes with an idea or a problem, really cool things come out of those conversations. This comes back to my passion for applied science. I love science that works.”

Learn more about how Michelle Chretien is an agent of change >

Read more from the National Inventors’ Day Series:

Part I: Xerox Celebrates National Inventors’ Day >

Part III: Guerino Sacripante: Sustainable Ink for Eco-Responsible Printing >

Part IV: Ajay Raghavan: Making Batteries Work Better >

Part V: Gary Starkweather Invented the Laser Printer Over 40 Years Ago >